Calcium carbide meter/speedy meter test

By: admin | Posted on: June 1, 2020

It is presumed by the way of the self proclaimed damp experts that the calcium carbide meter, or also referred to as the speedy meter, is in fact the most reliable form of moisture measurement when it comes to identification of rising damp. Unfortunately most don’t really understand the limitations of the damp measuring instruments, and don’t follow the guidance as per BRE DG245, where part of the sample should be put aside for the hygroscopicity determination.

I own, and have used a calcium carbide meter on many occasions, and in my opinion when measuring moisture, when there is the potential for rising damp and hygroscopic salts this instrument can be massively misleading. I personally only use this when inspecting flood damaged buildings that are more of a modern construction that would unlikely to be contaminated from hygroscopic salts, from a genuine long term rising damp. The reason for this is because you can’t determine what is actually going on regarding the amount of moisture, and giving the correct advice to fix the issues.

Example explanations

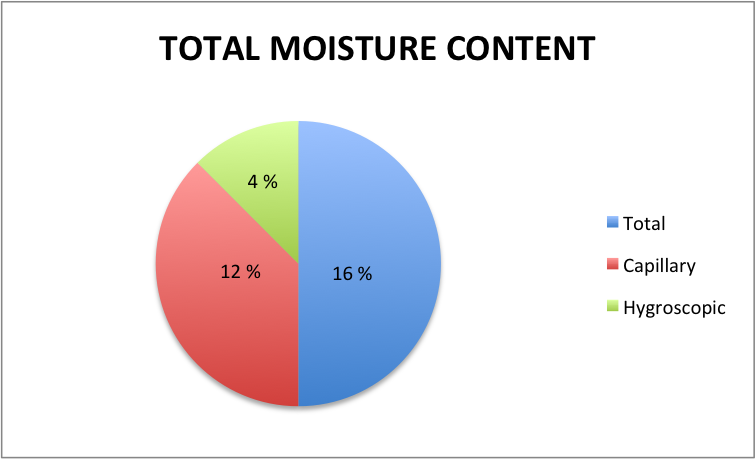

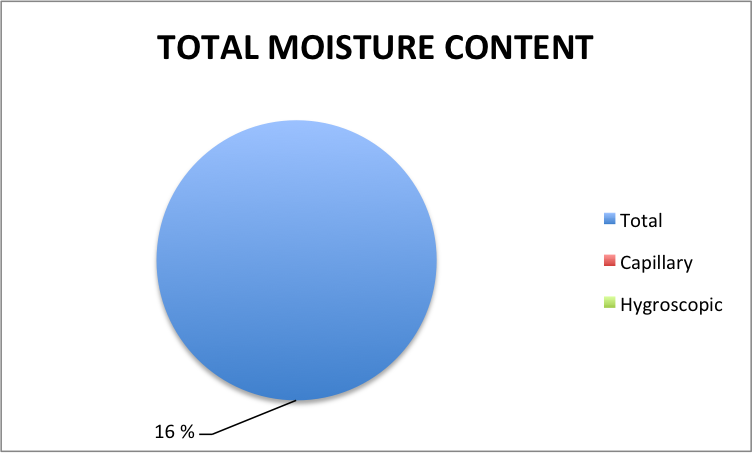

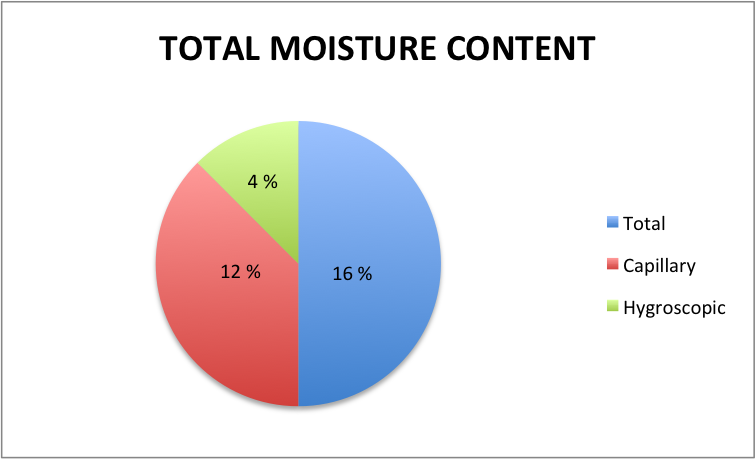

The below picture shows the total moisture content of a calcium carbide meter reading of a sample removed from the wall, and placed inside the speedy meter. As you can see it gives a total moisture content of 16 %. The total moisture content (16 %), is made up of the capillary moisture, and the hygroscopic moisture. The speedy meter doesn’t give a figure for these separate amounts, which is the misleading part.

The below picture shows an example of the total moisture content broken down into the capillary moisture, and the hygroscopic moisture.

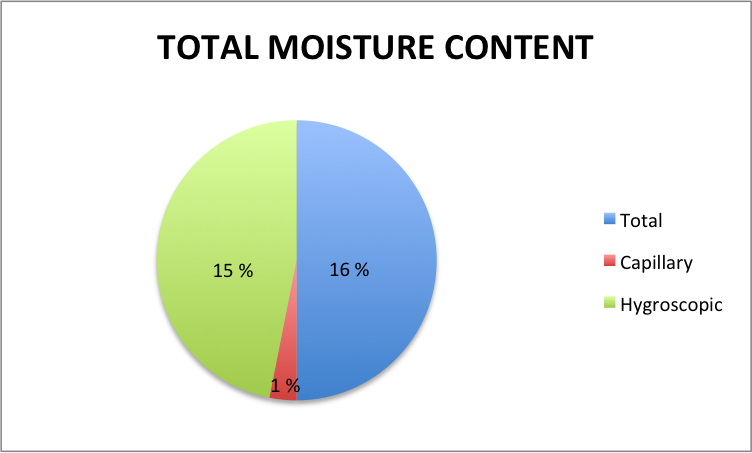

The below picture shows the same total moisture content as in the above picture, with a capillary moisture content of 1 %, and a hygroscopic moisture content of 15 %….. completely different.

The above images explain the total moisture content, and show that it is impossible for interpreting different moisture content results, without understanding the capillary moisture content, and hygroscopic moisture content on site.

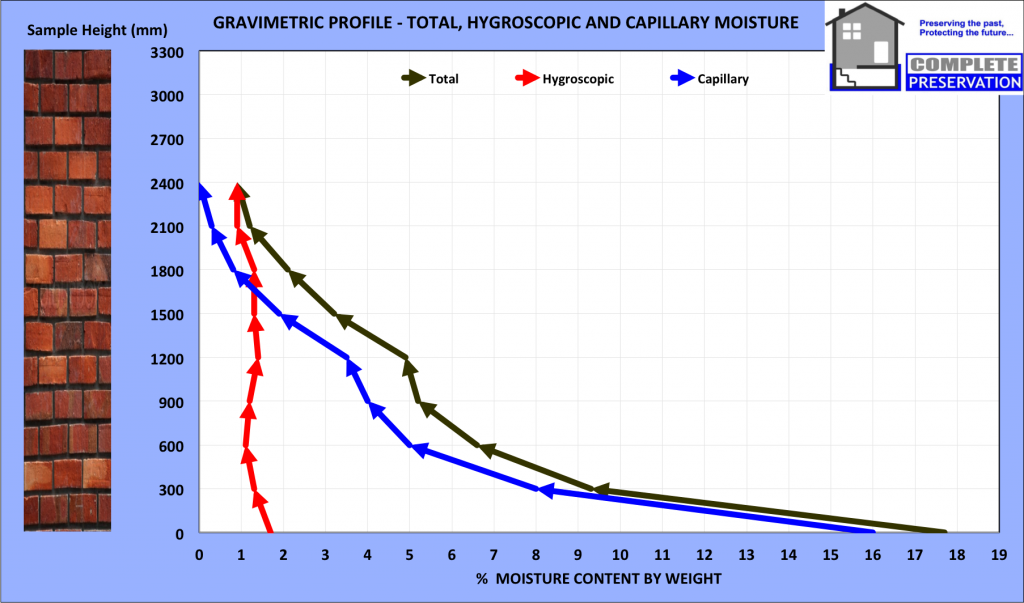

Lets now look at another example with some more guidance of why it is so important to differentiate between capillary moisture and hygroscopic moisture. This is from one of my recent surveys where a traditional solid wall property with no physical damp proof course installed has been damp proofed because it was presumed the property had genuine rising damp and needed a new damp proof course. During this survey I removed samples of plaster/mortar for analysis, and worked out the exact amounts of moisture using the gravimetric laboratory methodology. You can see in my graph below the total moisture content has been split up, to include the capillary and hygroscopic moisture content.

What does this graph show? This is the most important part…. what it shows here, is that there is a very high amount of capillary moisture content, and a low level of hygroscopic moisture content. This is not what you would see on a genuine long term rising damp issue, as you would normally see more of a distinguished hygroscopic salt band. This property actually had issues with drains that I picked up with our CCTV drain survey. The samples were also chemically tested for nitrates and chlorides (hygroscopic salts), and none of any significance were present. All of the data points to drainage issues or possible leaks, and this couldn’t be observed from an onsite calcium carbide meter test. This property needs to be dried down with a Corroventa desiccant tented drying equipment, and the drain issues rectified.

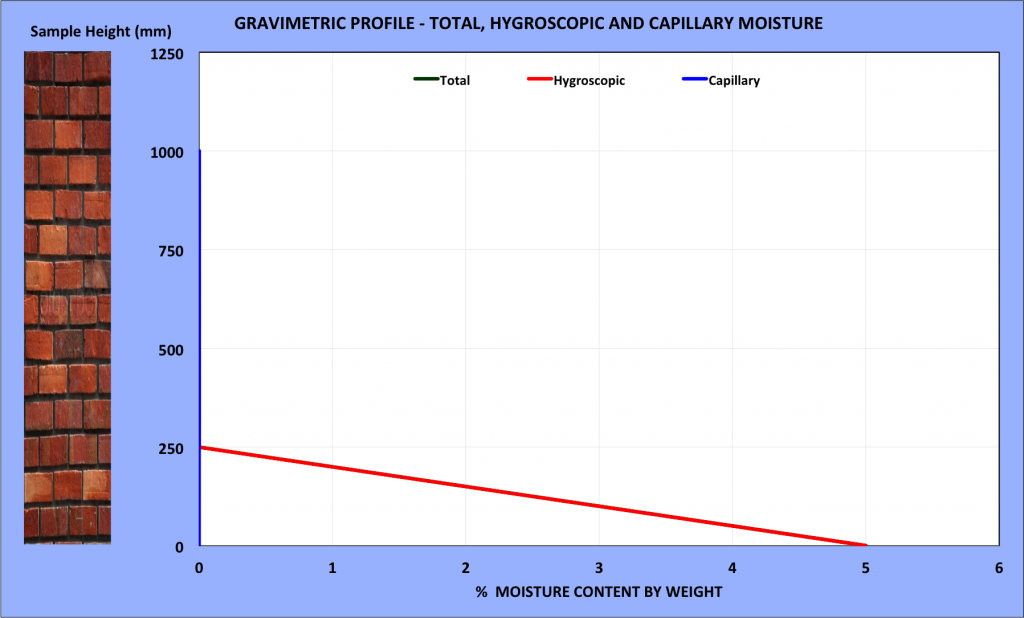

The below graph is something I see often where a physical damp proof course has been installed from new when a property was originally built. The total moisture content is 5%, and so is the hygroscopic moisture content, and the capillary moisture content is 0 %. How could you give suitable advice to your client if you couldn’t differentiate these moisture contents?

What this actually shows is that there is no capillary moisture. Capillary moisture content, is only present if there is a source of water/free moisture such as rising dampness. The amount of capillary moisture content will depend on the permeability, porosity and severity of the water ingress. The absence of capillary moisture indicates that a material is ‘dry’, that is not subject to water ingress from any source. This means normally that the damp proof course is most likely to be bridged, by plaster, debris in the cavity, or perhaps the floor screed. By also chemically testing the mortar samples for nitrates and chlorides, we can prove if these are present. If these are present as in this case, the repair was to remove the bridging issue, along with a suitable plaster repair.

Capillary moisture / Free moisture

The second component is the free moisture content which is only present if there is a source of water ingress such as rain penetration, rising dampness. The amount of free moisture will depend on the permeability, porosity and severity of the water ingress. The absence of free moisture indicates that a material is ‘dry’, that is not subject to water ingress from any source.

Ground water salts:

Not only is the distribution of moisture required, we also need to obtain details of past activity of rising dampness, and this can be obtained from the presence and distribution of ground water salts, basically chlorides and nitrates. Where a long term rising damp complex has existed, these salts will always mark the maximum height to which water has risen, and tend to form a concentration (‘salt band’) around the maximum height of rise. I often find on very old properties that have been subjected to long term rising damp over many years, sometimes two distinguished salt bands. Thus, even if water ceases to rise the salts will still remain and ‘mark’ the maximum height once reached. It is the relationship between the distribution of moisture and salts that is the basis of the investigation.

The information regarding speedy meter testing of moisture and gravimetrics has been published and documented by Building Research Establishment (BRE) for many years. The earliest copy I have is the TIL 29 version which was revised in April 1977, and the latest version is BRE DIGEST 245, also known as BRE DG 245. The latest version of this document is from 2007.

Very important extract below from DG 245 2007 edition

Experience has shown that some building materials possess an HMC of up to 5% even without the introduction of salts from external sources. Although only a rough indicator, the 5% threshold does represent a reasonable general guide to whether or not some kind of remedial treatment is needed. This emphasises the importance of the difference between the HMC and MC measured on samples. It can also be useful to establish the MC and HMC of wallpaper, plaster and render, although drying plaster above 35 °C will drive off hydration water bound within the plaster and must be avoided. The figure of 5% at the base of the wall (the wall/floor junction) can be taken as an approximate guide to the presence of rising damp. However, even at this low level of moisture there can be a risk of damage to finishes and rot to any timber that may be in contact with the wall.

If you like this kind of geeky facts on damp, you might like this one that has some screen shots from the British Standards www.completepreservation.co.uk/rising-damp/http://www.completepreservation.co.uk/rising-damp/